ʻO ka pauka keʻokeʻo e hoʻoheheʻe ana ma luna o ka ʻeke ʻōpala meaʻai no ka mea ʻo ka mea paheʻe (oleic acid amide, erucic acid amide) i hoʻohana ʻia e ka mea hana kiʻiʻoniʻoni ponoʻī e hoʻoheheʻe ʻia, a ʻo ke ʻano o ka mea paheʻe amide kuʻuna, ʻo ia ka neʻe ʻana o ka mea hana i ka ʻili o ke kiʻiʻoniʻoni, e hana ana i hoʻokahi papa lubricating molekala a hoʻemi i ke koina friction o ka ʻili o ke kiʻiʻoniʻoni. Eia nō naʻe, ma muli o ke kaumaha molekala liʻiliʻi o ka mea paheʻe amide, maʻalahi ka hoʻoheheʻe ʻia a i ʻole ka pauka, no laila maʻalahi ka pauka e noho ma luna o ka wili composite i ka wā o ke kaʻina hana hui ʻana o ke kiʻiʻoniʻoni, a e hoʻopili ʻia ka pauka ma ka wili rubber i ka wā o ke kaʻina hana kiʻiʻoniʻoni, e hopena ana i ka pauka keʻokeʻo maopopo ma ka huahana hope loa.

No ka hoʻoponopono ʻana i ka pilikia o ka maʻalahi o ka hoʻoheheʻe ʻana o nā mea paheʻe amide kuʻuna, ua hoʻomohala ʻo SILIKE i kahi huahana co-polysiloxane i hoʻololi ʻia e loaʻa ana nā hui hana organik ikaika -ʻAkena paheʻe ʻole Blooming moʻo SILIMERno ka ʻili plastik. ʻO ke kumumanaʻo hana o kēia huahana, ʻo ia ka hiki i nā hui hana ikaika ma ke kaulahao kalapona lōʻihi ke hana i kahi pilina kino a kemika paha me ka resin kumu, e hana ana ma ke ʻano he heleuma e hoʻokō ai i ka neʻe maʻalahi me ka ʻole o ka ua. Hāʻawi nā ʻāpana kaulahao polysiloxane ma ka ʻili i kahi hopena paheʻe. Nā māka i manaʻo ʻia:SILIMER5064, SILIMER5064MB1,SILIMER5064MB2, SILIMER5065HB…

1.Nā pōmaikaʻi meʻO ka SILIMER Series Non-Precipitation Slip Agent Masterbatch

- Hāʻawi i ka hana paheʻe mau loa i ka hala ʻana o ka manawa a ma lalo o nā kūlana wela kiʻekiʻe

- Hāʻawi i ke kūpaʻa, ka coefficient haʻahaʻa o ka friction, ka anti-blocking maikaʻi, a me ka ʻoi aku ka maikaʻi o ka ʻili o ka huahana hope loa.

- ʻAʻole pili i ka paʻi ʻana, ka sila wela, ka hui pū ʻana, ka transparency, a i ʻole ka noe

- Hoʻopau i nā pilikia pauka, palekana a ʻaʻohe ʻala

- Hoʻohana nui ʻia i nā kiʻiʻoniʻoni BOPP/CPP/PE/PP……

2.Kekahi ʻikepili hoʻāʻo hana pili

- Hoʻemi pono i ke koina friction, ʻaʻole ia e hoʻopilikia i kanoea me ka hoʻoili ʻana

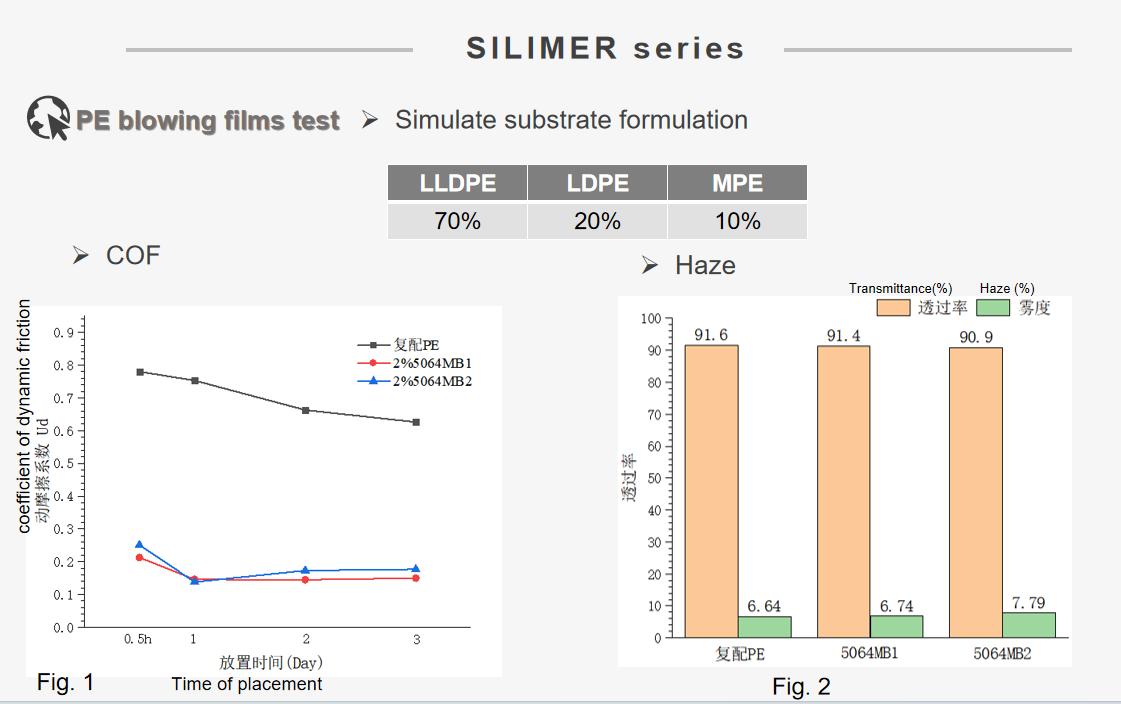

ʻO ke ʻano substrate i hoʻohālikelike ʻia: 70% LLDPE, 20% LDPE, 10% metallocene PE

E like me ka mea i hōʻike ʻia ma ke Kiʻi 1, ʻo ke koina friction o ke kiʻiʻoniʻoni ma hope o ka hoʻohui ʻana i 2%SILIMER 5064MB1a me 2%ʻO SILIMER 5064MB2ua hoʻemi nui ʻia i hoʻohālikelike ʻia me ka PE composite. Eia kekahi, a e like me ka mea i hōʻike ʻia ma ke Kiʻi 2, ʻo ka hoʻohui ʻana oSILIMER 5064MB1a meʻO SILIMER 5064MB2ʻaʻole i hoʻopilikia i ka noe a me ka transmittance o ke kiʻiʻoniʻoni.

- Paʻa ke koina friction

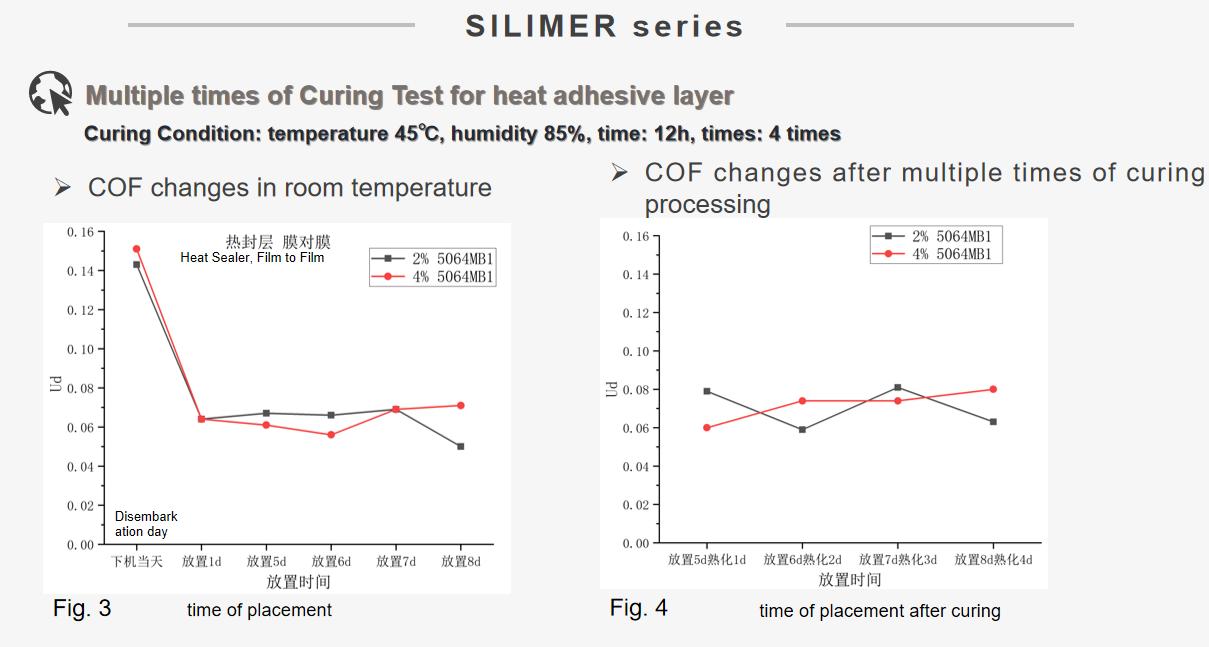

Nā kūlana ho'ōla: mahana 45 ℃, haʻahaʻa 85%, manawa 12h, 4 mau manawa

E like me ka mea i hōʻike ʻia ma ke Kiʻi 3 a me ke Kiʻi 4, hiki ke ʻike ʻia ʻo ke koina friction o ke kiʻiʻoniʻoni ma hope o ka hoʻohui ʻana i 2%SILIMER 5064MB1a me 4%SILIMER 5064MB1noho mau i kahi waiwai paʻa ma hope o ka hoʻōla ʻana i nā manawa he nui.

- ʻAʻole e hoʻomoe ʻia ka ʻili o ke kiʻiʻoniʻoni a ʻaʻole ia e hoʻopilikia i ka maikaʻi o nā lako a me ka huahana hope loa.

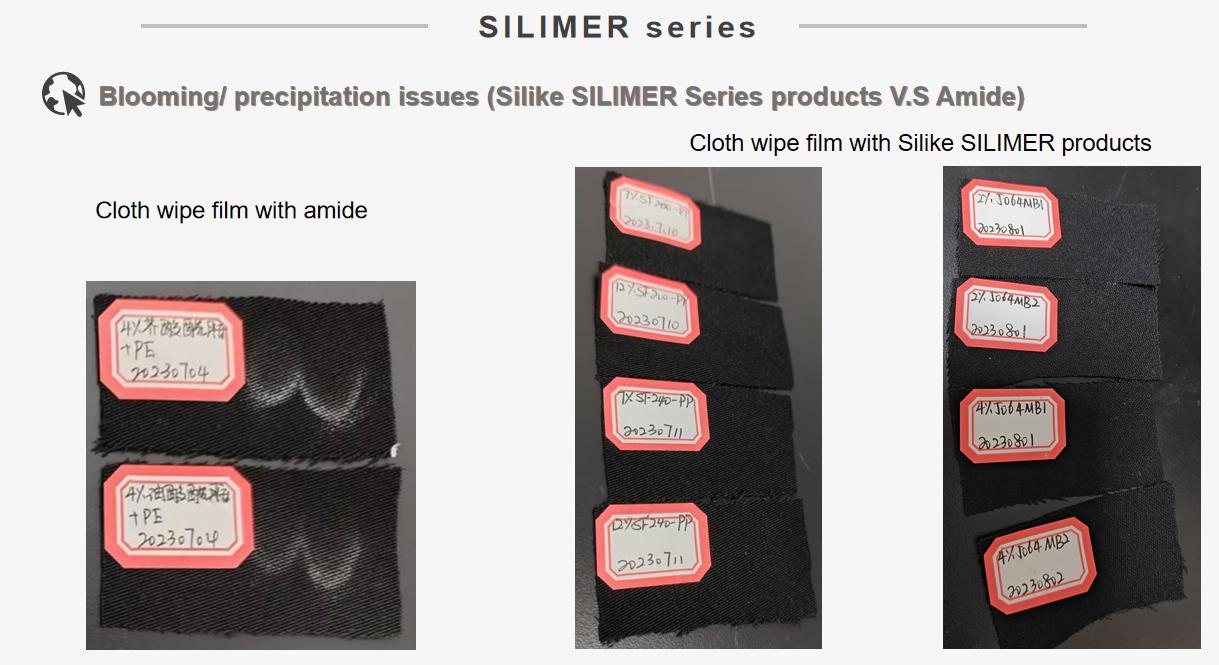

E like me ka mea i hōʻike ʻia ma ke kiʻi ma lalo nei, e hoʻohana i ka lole ʻeleʻele e holoi i ka ʻili o ke kiʻiʻoniʻoni me ka amide aHuahana SILIMERHiki ke ʻike ʻia i ka hoʻohālikelike ʻana me ka hoʻohana ʻana i nā mea hoʻohui amide, ʻaʻole hoʻopūʻiwa ka moʻo SILIMER a ʻaʻohe pauka hoʻopūʻiwa.

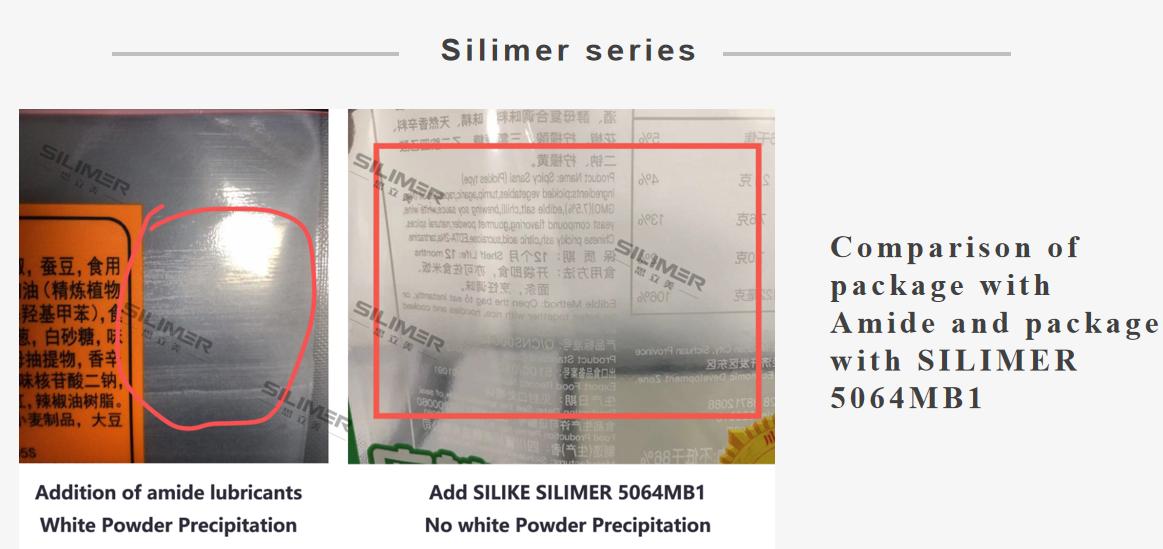

- E hoʻoponopono i ka pilikia o ka pauka keʻokeʻo i loko o ka wili hui a me ka ʻeke huahana hope loa

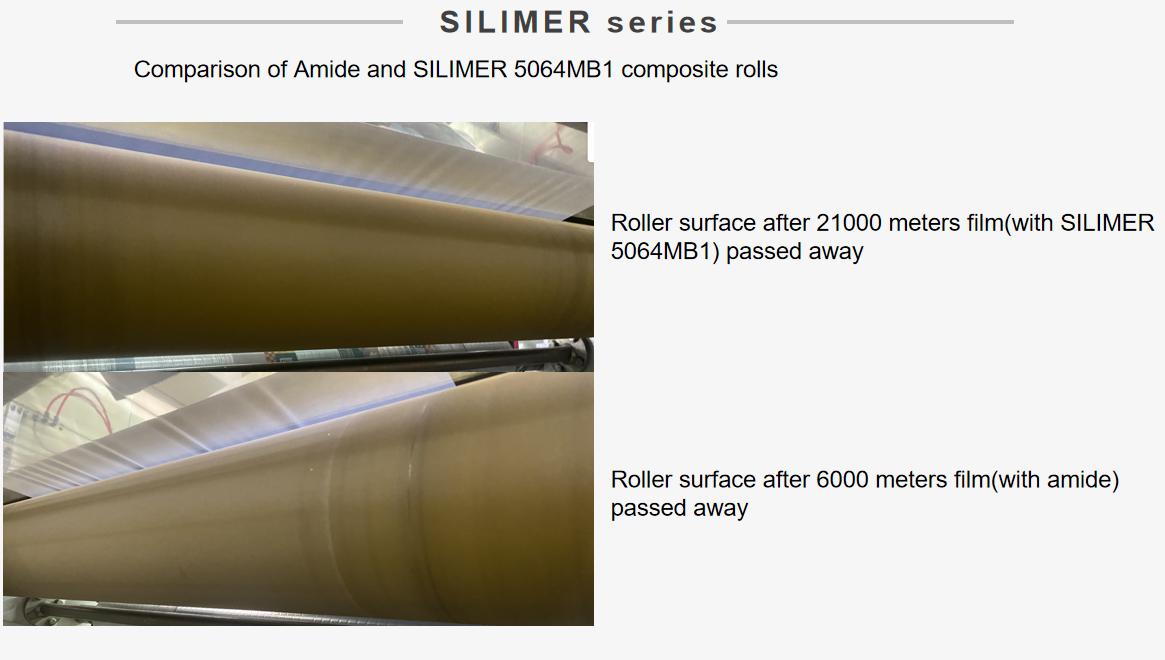

E like me ka mea i hōʻike ʻia ma ke kiʻi ma lalo nei, ma hope o ka hala ʻana o ka wili hui i 6000 mika o ke kiʻiʻoniʻoni me ka erucic acid amide, aia ka hōʻiliʻili ʻana o ka pauka keʻokeʻo, a aia kekahi pauka keʻokeʻo maopopo ma ka ʻeke huahana hope loa; Eia nō naʻe, hoʻohana ʻia meMoʻo SILIMERhiki iā mākou ke ʻike i ka wā i hala ai ka wili hui i 21000 mika, a ua maʻemaʻe a hou ka ʻeke huahana hope loa.

3. Ka Mana oSILIKESʻILIMERmoʻoʻaʻole e neʻe mau ana Paheʻe mau loaMea hoʻohui no ka hoʻopili palupalu.

E hoʻololi i ka palekana o kāu ʻōpala meaʻai! Luhi i ka ua o ka pauka keʻokeʻo i loko o kāu mau ʻeke ʻōpala hui a i ʻole nā kiʻi ʻē aʻe? Mākaukau no kahi hoʻololi?Moʻo SILIKE SILIMERʻAʻole e neʻe mau ana ka mea hoʻohui paheʻe mau loa no ka hoʻopili ʻana i ka ʻūpā maʻalahi,mea hoʻoheheʻe ʻaʻole pua, ʻaʻole-ua paheʻe luna masterbatch no ka ʻili plastik, hoʻopau i nā pilikia pauka, e hōʻoiaʻiʻo ana i kahi ʻike hoʻopili kīnā ʻole a maʻemaʻe. E kāhea iā mākou i kēia manawa! E hoʻololi pū kākou i kāu ʻike hoʻopili!

Eia mākou e hana i nā hoʻonā i hana kūikawā ʻia nou wale nō!ʻO ka moʻo SILIMER non-precipitation slip agent masterbatchkūpono i nā noi plastik like ʻole, ʻaʻole i kaupalena ʻia i nā kiʻiʻoniʻoni hoʻopili (BOPP, CPP, BOPET, EVA, kiʻiʻoniʻoni TPU, LDPE, a me nā kiʻiʻoniʻoni LLDPE.) hāʻawi pū i nā hopena paheʻe paʻa a mau loa no nā pepa a me nā huahana polymer ʻē aʻe kahi e makemake ʻia ai ka paheʻe a me nā waiwai ʻili i hoʻomaikaʻi ʻia.

Ka manawa hoʻouna: Ian-19-2024