Hoʻolauna i nā Polyolefins a me ka Film Extrusion

ʻO nā Polyolefins, kahi papa o nā mea macromolecular i hana ʻia mai nā monomers olefin e like me ka ethylene a me ka propylene, ʻo ia nā plastics i hana nui ʻia a hoʻohana ʻia ma ka honua holoʻokoʻa. Loaʻa ko lākou laha mai ka hui pū ʻana o nā waiwai, me ke kumukūʻai haʻahaʻa, ka hiki ke hana maikaʻi loa, ke kūpaʻa kemika koʻikoʻi, a me nā ʻano kino kūpono. Ma waena o nā noi like ʻole o nā polyolefins, paʻa nā huahana kiʻiʻoniʻoni i kahi kūlana koʻikoʻi, e lawelawe ana i nā hana koʻikoʻi i ka ʻōpala meaʻai, nā uhi mahiʻai, ka ʻōpala ʻoihana, nā huahana lapaʻau a me nā huahana hoʻomaʻemaʻe, a me nā waiwai kūʻai o kēlā me kēia lā. ʻO nā resins polyolefin maʻamau i hoʻohana ʻia no ka hana kiʻiʻoniʻoni me ka polyethylene (PE) - e hoʻopuni ana iā Linear Low-Density Polyethylene (LLDPE), Low-Density Polyethylene (LDPE), a me High-Density Polyethylene (HDPE) - a me ka polypropylene (PP).

ʻO ka hana ʻana o nā kiʻiʻoniʻoni polyolefin e hilinaʻi nui ʻia ma ka ʻenehana extrusion, me Blown Film Extrusion a me Cast Film Extrusion nā hana nui ʻelua.

1. Kaʻina Hana Hoʻopuka Kiʻiʻoniʻoni Puhi

ʻO ka hoʻokuʻu ʻana i ka ʻili puhi ʻia kekahi o nā ʻano hana maʻamau no ka hana ʻana i nā ʻili polyolefin. ʻO ke kumu nui e pili ana i ka hoʻokuʻu ʻana i kahi polymer i hoʻoheheʻe ʻia i luna ma o kahi make annular, e hana ana i kahi parison tubular lahilahi. Ma hope iho, hoʻokomo ʻia ka ea i hoʻopaʻa ʻia i loko o kēia parison, e hoʻoulu ai i loko o kahi pehu me ke anawaena ʻoi aku ka nui ma mua o ka make. I ka piʻi ʻana o ka pehu, ua hoʻomaʻalili ikaika ʻia a hoʻopaʻa ʻia e kahi apo ea waho. A laila ua hiolo ka pehu i hoʻomaʻalili ʻia e kahi hoʻonohonoho o nā wili nip (pinepine ma o kahi kiʻikuhi hiolo a i ʻole A-frame) a ma hope ua huki ʻia e nā wili traction ma mua o ka ʻōwili ʻia ʻana ma luna o kahi ʻōwili. ʻO ke kaʻina hana ʻili puhi ʻia e loaʻa pinepine ai nā kiʻiʻoniʻoni me ke kuhikuhi biaxial, ʻo ia hoʻi ke hōʻike nei lākou i kahi kaulike maikaʻi o nā waiwai mechanical ma ke kuhikuhi mīkini (MD) a me ke kuhikuhi transverse (TD), e like me ka ikaika tensile, ke kū'ē ʻana i ka haehae, a me ka ikaika hopena. Hiki ke hoʻomalu ʻia ka mānoanoa o ka ʻili a me nā waiwai mechanical ma ka hoʻoponopono ʻana i ka lakio pahū (BUR - lakio o ke anawaena pehu i ke anawaena make) a me ka lakio huki (DDR - lakio o ka wikiwiki lawe i ka wikiwiki extrusion).

2. Kaʻina Hana Hoʻopuka Kiʻiʻoniʻoni

ʻO ka hoʻoheheʻe ʻana i ka ʻiliʻili i hoʻolei ʻia kekahi kaʻina hana hana koʻikoʻi no nā ʻiliʻili polyolefin, kūpono loa no ka hana ʻana i nā ʻiliʻili e koi ana i nā waiwai optical kiʻekiʻe (e laʻa, ke ʻano moakāka kiʻekiʻe, ka ʻōlinolino kiʻekiʻe) a me ke ʻano like o ka mānoanoa. Ma kēia kaʻina hana, ua hoʻopuka ʻia ka polymer i hoʻoheheʻe ʻia ma o kahi T-die pālahalaha, ʻano slot, e hana ana i kahi pūnaewele hoʻoheheʻe like. A laila huki koke ʻia kēia pūnaewele ma luna o ka ʻili o hoʻokahi a ʻoi aku paha nā ʻōwili anuanu wikiwiki, i hoʻomaʻalili ʻia i loko. Hoʻopaʻa koke ka heheʻe i ka wā e pili ai me ka ʻili ʻōwili anu. Loaʻa i nā ʻiliʻili i hoʻolei ʻia nā waiwai optical maikaʻi loa, kahi manaʻo palupalu, a me ka sila wela maikaʻi. ʻO ka mana pololei ma luna o ka hakahaka lehelehe make, ka mahana o ka ʻōwili anuanu, a me ka wikiwiki o ka wili e ʻae ai i ka hoʻoponopono pololei ʻana i ka mānoanoa o ka ʻiliʻili a me ka maikaʻi o ka ʻili.

Nā pilikia kiʻekiʻe 6 o ka hoʻokuʻu ʻana i ka kiʻiʻoniʻoni Polyolefin

ʻOiai ke oʻo ʻana o ka ʻenehana extrusion, pinepine nā mea hana i nā pilikia hana i ka hana maoli ʻana o nā kiʻiʻoniʻoni polyolefin, ʻoiai ke hoʻoikaika nei no ka hana kiʻekiʻe, ka pono, nā ana lahilahi, a me ka hoʻohana ʻana i nā resins hana kiʻekiʻe hou. ʻAʻole wale kēia mau pilikia e pili i ke kūpaʻa o ka hana ʻana akā pili pololei hoʻi i ka maikaʻi o ka huahana hope loa a me ke kumukūʻai. ʻO nā pilikia nui:

1. Ka haki heheʻe (ʻIli mano): ʻO kēia kekahi o nā hemahema maʻamau i ka extrusion kiʻiʻoniʻoni polyolefin. Ma ke ʻano macroscopic, hōʻike ʻia ia ma ke ʻano he mau ripples transverse periodic a i ʻole kahi ʻili ʻino ʻole ma luna o ke kiʻiʻoniʻoni, a i ʻole i nā hihia koʻikoʻi, nā distortions ʻoi aku ka ʻike. Hana nui ʻia ka haki heheʻe i ka wā e ʻoi aku ai ka nui o ka shear rate o ka polymer melt e puka ana i ka make ma mua o kahi waiwai koʻikoʻi, e alakaʻi ana i nā oscillations stick-slip ma waena o ka paia make a me ka nui o ka heheʻe, a i ʻole i ka wā e ʻoi aku ai ke kaumaha extensional ma ka puka make ma mua o ka ikaika heheʻe. Hoʻopilikia nui kēia hemahema i nā waiwai optical o ke kiʻiʻoniʻoni (clarity, gloss), ka laumania o ka ʻili, a hiki ke hoʻohaʻahaʻa i kona mau waiwai mechanical a me ka pale.

2. Die Drool / Die Build-up: Pili kēia i ka hōʻiliʻili mālie ʻana o nā huahana polymer degradation, nā ʻāpana kaumaha molekala haʻahaʻa, nā mea hoʻohui i hoʻopuehu maikaʻi ʻole ʻia (e laʻa, nā pigments, nā mea antistatic, nā mea paheʻe), a i ʻole nā gels mai ka resin ma nā kihi lehelehe make a i loko o ka lua make. Hiki i kēia mau waihona ke hemo i ka wā o ka hana ʻana, e haumia ana i ka ʻili o ke kiʻiʻoniʻoni a hana i nā kīnā e like me nā gels, nā kaha, a i ʻole nā kalai, a laila e hoʻopilikia ai i ke ʻano a me ka maikaʻi o ka huahana. I nā hihia koʻikoʻi, hiki i ka hōʻiliʻili ʻana o ka make ke ālai i ka puka o ka make, e alakaʻi ana i nā ʻokoʻa o ke ana, ka haehae ʻana o ke kiʻiʻoniʻoni, a i ka hopena e koi ana i ka pani ʻana o ka laina hana no ka hoʻomaʻemaʻe ʻana i ka make, e hopena ana i nā pohō nui i ka pono o ka hana a me ka hoʻonele ʻana i nā mea maka.

3. Kaomi Extrusion Kiʻekiʻe a me ka Fluctuation: Ma lalo o kekahi mau kūlana, ʻoiai ke hana ʻana i nā resins viscosity kiʻekiʻe a i ʻole ka hoʻohana ʻana i nā hakahaka make liʻiliʻi, hiki i ke kaomi i loko o ka ʻōnaehana extrusion (ʻoi aku hoʻi ma ke poʻo extruder a me ka make) ke lilo i kiʻekiʻe loa. ʻAʻole wale ke kaomi kiʻekiʻe e hoʻonui i ka hoʻohana ʻana i ka ikehu akā hoʻoweliweli pū kekahi i ka lōʻihi o nā lako (e laʻa, wili, barela, make) a me ka palekana. Eia kekahi, ʻo nā fluctuations paʻa ʻole i ke kaomi extrusion e hoʻoulu pololei i nā loli i ka hoʻopuka hoʻoheheʻe, e alakaʻi ana i ka mānoanoa o ka ʻiliʻili like ʻole.

4. Ka Huakaʻi Palena: No ka pale ʻana a i ʻole ka hōʻemi ʻana i nā pilikia e like me ka haki heheʻe a me ka hōʻiliʻili ʻana o ka make, koi pinepine ʻia nā mea hana e hōʻemi i ka wikiwiki o ka wili extruder, a laila e kaupalena ana i ka hana o ka laina hana. Hoʻopilikia pololei kēia i ka pono o ka hana ʻana a me ke kumukūʻai hana no kēlā me kēia ʻāpana o ka huahana, e paʻakikī ai ke hoʻokō i nā koi o ka mākeke no nā kiʻiʻoniʻoni nui a haʻahaʻa ke kumukūʻai.

5. Paʻakikī i ka Mana Ana: ʻO ka paʻa ʻole o ke kahe heheʻe, ka hoʻolaha like ʻole o ka mahana ma waena o ka make, a me ka hōʻiliʻili ʻana o ka make hiki ke kōkua i nā ʻokoʻa o ka mānoanoa o ke kiʻiʻoniʻoni, ma ke ʻano transverse a me ka longitudinal. Hoʻopilikia kēia i ka hana hana o ke kiʻiʻoniʻoni ma hope a me nā ʻano hoʻohana hope.

6. Hoʻololi Paʻakikī ʻana o ka Resin: Ke hoʻololi nei ma waena o nā ʻano like ʻole a i ʻole nā papa o nā resins polyolefin, a i ʻole ke hoʻololi nei i nā masterbatches kala, he paʻakikī pinepine ka hoʻomaʻemaʻe loa ʻana i nā mea i koe mai ka holo mua ʻana mai ka extruder a me ka make. Ke alakaʻi nei kēia i ka hui pū ʻana o nā mea kahiko a me nā mea hou, e hana ana i nā mea hoʻololi, e hoʻolōʻihi ana i nā manawa hoʻololi, a me ka hoʻonui ʻana i nā helu ʻōpala.

Ke kāohi nei kēia mau pilikia hana maʻamau i nā hana a nā mea hana kiʻiʻoniʻoni polyolefin e hoʻonui i ka maikaʻi o ka huahana a me ka pono o ka hana ʻana, a ke pale nei hoʻi i ka hoʻohana ʻana i nā mea hou a me nā ʻano hana hana holomua. No laila, ʻo ka ʻimi ʻana i nā hopena kūpono e lanakila ai i kēia mau pilikia he mea nui ia no ka hoʻomau a me ke olakino o ka ʻoihana extrusion kiʻiʻoniʻoni polyolefin holoʻokoʻa.

Nā Hoʻonā no ke Kaʻina Hana Hoʻopuka Kiʻiʻoniʻoni Polyolefin: Nā Kōkua Hana Polymer (PPAs)

ʻO nā Polymer Processing Aids (PPAs) he mau mea hoʻohui hana nona ka waiwai nui i ka hoʻomaikaʻi ʻana i ke ʻano rheological o ka polymer melts i ka wā o ka extrusion a me ka hoʻololi ʻana i kā lākou pilina me nā ʻili o nā lako, a laila e lanakila ai i nā ʻano pilikia hana like ʻole a hoʻonui i ka pono hana a me ka maikaʻi o ka huahana.

1. Nā PPA i hoʻokumu ʻia i ka Fluoropolymer

ʻAno Kemika a me nā ʻAno: ʻO kēia nā papa PPA i hoʻohana nui ʻia i kēia manawa, ʻoi aku ka ʻenehana, a hōʻike ʻia ka maikaʻi. ʻO ka maʻamau he mau homopolymers a i ʻole copolymers i hoʻokumu ʻia ma nā monomers fluoroolefin e like me vinylidene fluoride (VDF), hexafluoropropylene (HFP), a me tetrafluoroethylene (TFE), me nā fluoroelastomers ka mea i hōʻike nui ʻia. ʻO nā kaulahao molekala o kēia mau PPA he waiwai nui i nā pilina CF kiʻekiʻe-ikaika, haʻahaʻa-polarity, e hāʻawi ana i nā waiwai physicochemical kū hoʻokahi: ikehu ʻili haʻahaʻa loa (e like me ka polytetrafluoroethylene/Teflon®), kūpaʻa wela maikaʻi loa, a me ka inertness kemika. ʻO ka mea koʻikoʻi, hōʻike pinepine nā PPA fluoropolymer i ka launa maikaʻi ʻole me nā matrices polyolefin non-polar (e like me PE, PP). ʻO kēia incompatibility kahi mea nui e pono ai no ko lākou neʻe pono ʻana i nā ʻili metala o ka make, kahi e hana ai lākou i kahi uhi lubricating dynamic.

Nā Huahana ʻElele: ʻO nā lama alakaʻi ma ka mākeke honua no nā PPA fluoropolymer e komo pū ana me ka moʻo Viton™ FreeFlow™ a Chemours a me ka moʻo Dynamar™ a 3M, nona kahi mahele mākeke koʻikoʻi. Eia kekahi, hoʻohana ʻia kekahi mau māka fluoropolymer mai Arkema (moʻo Kynar®) a me Solvay (Tecnoflon®) ma ke ʻano he mau ʻāpana koʻikoʻi i loko o nā ʻano hana PPA.

2. Nā Kōkua Hana Hana i hoʻokumu ʻia i ka Silicone (PPAs)

ʻAno Kemika a me nā ʻAno: ʻO nā mea hana nui i kēia papa o nā PPA he polysiloxanes, i kapa pinepine ʻia he silicones. ʻO ke kuamoʻo polysiloxane he mau ʻātoma silicon a me oxygen (-Si-O-), me nā hui organik (ʻo ka methyl maʻamau) i hoʻopili ʻia i nā ʻātoma silicon. Hāʻawi kēia ʻano molekala kū hoʻokahi i nā mea silicone me ka haʻahaʻa loa o ka ʻili, ke kūpaʻa wela maikaʻi loa, ka maʻalahi maikaʻi, a me nā waiwai ʻaʻole e hoʻopili i nā mea he nui. E like me nā PPA fluoropolymer, hana nā PPA silicone-based ma ka neʻe ʻana i nā ʻili metala o nā lako hana e hana i kahi papa lubricating.

Nā Hiʻohiʻona Hoʻohana: ʻOiai ʻo nā PPA fluoropolymer e hoʻomalu i ka ʻāpana extrusion kiʻi polyolefin, hiki i nā PPA silicone-based ke hōʻike i nā pono kūikawā a i ʻole e hana i nā hopena synergistic ke hoʻohana ʻia i nā hiʻohiʻona noi kikoʻī a i ʻole e hui pū me nā ʻōnaehana resin kikoʻī. No ka laʻana, hiki ke noʻonoʻo ʻia no nā noi e koi ana i nā coefficients haʻahaʻa loa o ka friction a i ʻole kahi e makemake ʻia ai nā ʻano ʻili kikoʻī no ka huahana hope loa.

Ke kū nei i nā pāpā Fluoropolymer a i ʻole nā pilikia lako PTFE?

E hoʻoponopono i nā pilikia o ka hoʻopuka ʻana i ka kiʻiʻoniʻoni Polyolefin me nā hoʻonā PPA ʻole PFAS-Nā mea hoʻohui Polymer Fluorine Free a SILIKE

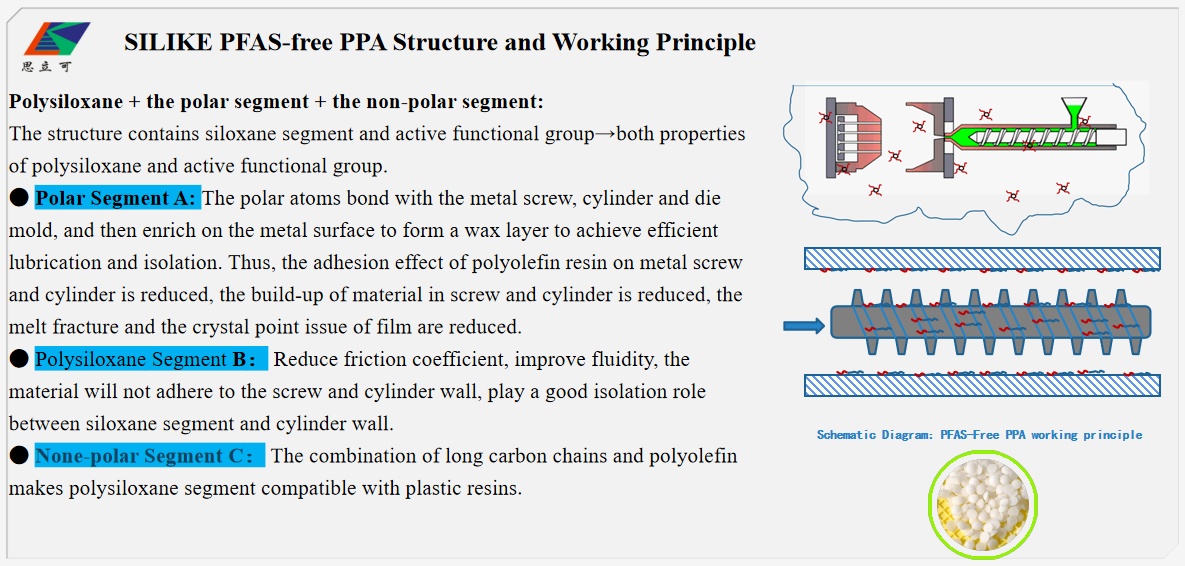

Lawe ʻo SILIKE i kahi ala proactive me kāna mau huahana moʻo SILIMER, e hāʻawi ana i nā mea houNā mea kōkua hana polymer ʻole PFAS (PPAs)). Loaʻa i kēia laina huahana piha nā PPA maʻemaʻe ʻole PFAS 100%.nā mea hoʻohui Polymer PPA ʻaʻohe fluorine, a meNā haku hana PPA ʻole PFAS a me fluorine ʻole.Naka hoʻopau ʻana i ka pono no nā mea hoʻohui fluorine, kōkua kēia mau hana hana i ka hoʻoikaika nui ʻana i ke kaʻina hana no LLDPE, LDPE, HDPE, mLLDPE, PP, a me nā kaʻina hana extrusion kiʻi polyolefin like ʻole. Hoʻohālikelike lākou me nā lula kaiapuni hou loa me ka hoʻoikaika ʻana i ka pono hana, ka hoʻemi ʻana i ka downtime, a me ka hoʻomaikaʻi ʻana i ka maikaʻi o ka huahana holoʻokoʻa. Lawe mai nā PPA ʻole PFAS a SILIKE i nā pono i ka huahana hope loa, me ka hoʻopau ʻana i ka haki heheʻe (sharkskin), ka laumania i hoʻonui ʻia, a me ka maikaʻi o ka ʻili.

Inā ʻoe e hakakā nei me ka hopena o nā pāpā fluoropolymer a i ʻole ka nele o PTFE i kāu mau kaʻina hana extrusion polymer, hāʻawi ʻo SILIKEnā koho ʻē aʻe i nā fluoropolymer PPAs/PTFE, Nā mea hoʻohui PFAS-free no ka hana ʻana i nā kiʻiʻoniʻonii hoʻopilikino ʻia e hoʻokō i kāu mau pono, me ke ʻole o nā hoʻololi kaʻina hana e pono ai.

Ka manawa hoʻouna: Mei-15-2025