Ke Hoʻomaopopo ʻana i ka Fiber a me ka Monofilament:

ʻO ka Fiber a me ka Monofilament he mau kaula hoʻokahi a mau paha o kahi mea, ʻo ia hoʻi he polymer synthetic e like me ka nylon, polyester, a i ʻole polypropylene. Hoʻohālikelike ʻia kēia mau filaments e ko lākou ʻano hoʻokahi-ʻāpana, i kūʻē i nā olonā multifilament i loaʻa i nā kaula he nui i wili ʻia a i hui pū ʻia paha.

Loaʻa nā noi o ka Fiber a me ka Monofilament ma nā ʻoihana like ʻole, me nā lole, ka lawaiʻa, a me nā kaʻina hana ʻoihana. I loko o nā lole, hiki ke hoʻohana ʻia nā olonā monofilament no nā noi e like me nā lole sheer, nā ʻupena, a me ka mesh. I ka lawaiʻa, hoʻohana pinepine ʻia nā laina monofilament no ka lawaiʻa lawaiʻa a me ke kālepa ma muli o ko lākou ikaika, ka maʻalahi, a me ke kūʻē ʻana i ka abrasion. Hoʻohana ʻia ka monofilament ma ke ʻano o nā sutures lapaʻau, kahi e hoʻohana ʻia ai nā kaula hoʻokahi o nā mea biocompatible no ka humuhumu ʻana i nā ʻeha a i ʻole nā ʻoki ʻoki.

ʻO ka maʻamau, ma ke ʻano ikaika o ka hana ʻana i ka polymer, ʻo ka ʻimi no ka pono a me ka maikaʻi i ka fiber a i ʻole ka monofilament extrusion he mea pau ʻole. Hoʻoikaika nā mea hana no nā hopena hou e hoʻoikaika i ka hana hana, hōʻemi i ka downtime, a hōʻemi i ka ʻōpala. Hoʻololi kēia kaʻina hana hana koʻikoʻi i nā resins polymer i nā kaula hoʻomau i hana ʻia no nā ʻano noi like ʻole, mai nā textiles a me nā sutures lapaʻau a hiki i nā ʻāpana ʻoihana.

Nā Pilikia ma ka Fibera meHoʻopuka Monofilament:

ʻO ka hōʻiliʻili ʻana o ka make, ka haumia ʻana o ka ʻeke pale, a me ka haki ʻana o ke kaula e hoʻopilikia ai i nā mea hana, e hoʻopilikia ana i ka maikaʻi o ka huahana hope loa a me ka hoʻonui ʻana i ka downtime a me nā kumukūʻai. Ua hoʻohana ʻia nā fluoropolymers kuʻuna a me nā kemika i loaʻa iā PFAS.nā mea kōkua hana polymer kūpono (PPAs)Akā, i ka wā e kau ai nā lula hou ma ʻEulopa a me ʻAmelika Hui Pū ʻIa i nā palena a me nā pāpā i ka hoʻohana ʻana i nā fluoropolymers, a me nā kemika i loaʻa iā PFAS, ʻimi nā mea hana i nā koho ʻē aʻe e kūlike me kēia mau lula e hiki mai ana me ka ʻole o ka hoʻopilikia ʻana i ka hana.

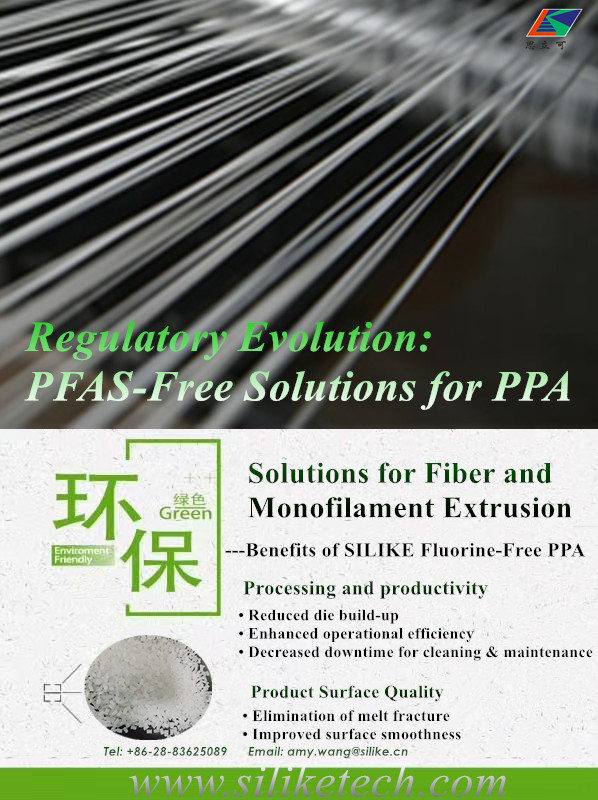

ʻO ka PPA ʻole PFAS a SILIKEHoʻonā:

Nā Kōkua Hana Polymer ʻole PFAS a SILIKEe kū mai ma ke ʻano he hopena holomua i nā pilikia e kū nei.Nā Kōkua Hana Polymer ʻAʻohe Fluorine (PPA) SILIMER 5090kūlike me nā lula EU e hiki mai ana, e hoʻokele ana mai nā palena a me nā pāpā i nā fluoropolymers a me nā kemika i loaʻa iā PFAS.

ʻO kā mākou hopena hou e hōʻoiaʻiʻo ana i ka hana ʻana o ka polymer kuleana, e hoʻokau mua ana i ka hoʻomau me ka ʻole o ka hoʻopilikia ʻana i ka maikaʻi a i ʻole ka pono.

ʻO nā noi maʻamau e pōmaikaʻi mai ka hoʻohana ʻana:

• Kiʻiʻoniʻoni i puhi ʻia a hoʻolei ʻia

• Hoʻopuka ʻia ʻana o ka ʻiliʻili multilayer

• Hoʻopuka ʻana i ke kaula a me ka paipu

• Hoʻopuka ʻana i ka fiber a me ka monofilament

• Ka hana ʻana i ka petrochemical

• Hoʻopuka pepa

• Hoʻohuihui ʻana

Ke wehe nei i ke ala i ka Optimal Fiber a me ka Monofilament Extrusion!

Ma ke aupuni o nā make haiki a me nā nui kiʻekiʻe e hana ana i nā olonā lahilahi loa, ʻo ka hōʻiliʻili ʻana o ka make a me ka pale pack, ka hoʻopili ʻana o ka make, a me ka haki ʻana o ke kaula e hōʻike ana i nā pilikia e alakaʻi ana i ka hoʻonele a me ka manawa hana ʻole. Pehea e hoʻoponopono ai i nā pilikia o ka Fiber a me ka Monofilament Extrusion?

E wehe i ka pono ma ka hana ʻana o ka fiber a me ka monofilament me ʻO ka PPA ʻole PFAS a SILIKE!

1. Hoʻemi ʻana i ka make a me ka pale pack buildingup:ʻO ka hoʻokumu hou ʻana oNā Kōkua Hana Polymer ʻAʻohe Fluorine SILIMER(PPA)SILIMER 5090e hōʻemi pono i ka hōʻiliʻili ʻana o nā haumia a me nā koena polymer i nā make haiki a me nā ʻeke pale. Hoʻomaopopo kēia hōʻemi i kahi kaʻina hana extrusion maʻalahi a pale i ka pono no ka hoʻomaʻemaʻe pinepine a me ka mālama ʻana.

2. Kāohi ʻana i ka Plugging MakeʻO ke ʻano kūikawā o Nā Kōkua Hana Polymer ʻAʻohe Fluorine SILIMER(PPA)SILIMER 5090kōkua i ka pale ʻana i ka hoʻopili ʻana o ka make, kahi pilikia maʻamau e hoʻopilikia ai i ke kahe mau o ka polymer ma o ka make. ʻO kēia ke alakaʻi i ka extrusion kūlike a me nā huahana hopena kiʻekiʻe.

3. Hoʻēmi i ka haki ʻana o ke kaulaMa ka hoʻonui ʻana i nā waiwai kahe polymer,Nā Kōkua Hana Polymer ʻAʻohe Fluorine SILIMER(PPA)SILIMER 5090kōkua i ka hōʻemi ʻana i ka haki ʻana o ke kaula i ka wā o ka extrusion. ʻAʻole wale kēia e hoʻomaikaʻi i ka pono hana akā hoʻemi pū i ka ʻōpala, e hopena ana i ka mālama kālā no nā mea hana.

4. Ka Hoʻemi ʻana i ke Kumukūʻai a me ka Hoʻemi ʻana i ka Manawa HanaʻO ka hui pū ʻana o ka hoʻemi ʻana o ka make a me ka hōʻiliʻili pale, ka pale ʻana i ka die plugging, a me ka hoʻēmi ʻana i ka haki ʻana o ke kaula e kōkua pū i ka mālama kālā nui a me ka hoʻemi ʻana i ka downtime. Hiki i nā mea hana ke hoʻokō i nā nui hana kiʻekiʻe me ka hoʻomaikaʻi ʻana i ka pono.

Ua mākaukau ʻoe e hoʻokiʻekiʻe i kāu mau kaʻina hana extrusion? E ʻimi i ka hiki oKōkua ka hana ʻana o ka PFAS-free Polymer a SILIKE iā SILIMER 5090no ka hana kiʻekiʻe loa i ka hana fiber a me ka monofilament.

Akā, ʻaʻole kēlā wale nō - E ʻike i nā noi palena ʻole oNā Kōkua Hana Polymer ʻAʻohe Fluorine SILIMER(PPA)SILIMER 5090ma ʻō aku o ka Fiber a me ka Monofilament Extrusion, Mai ka ʻoniʻoni puhi ʻia, ka ʻoniʻoni hoʻolei ʻia, ke kaula, nā paipu, Fiber, a me ka Monofilament Extrusion, Sheet extrusion, Compounding i petrochemicals, metallocene polypropylene, a i ʻole metallocene PE.Nā Kōkua Hana Polymer ʻole PFAS a SILIKEʻo ia kou kī i ka maikaʻi loa ʻo Compliance Meets Innovation, e kūlike me nā lula EU e hiki mai ana, e pale ana i nā palena a me nā pāpā i nā fluoropolymers a me nā kemika i loaʻa iā PFAS. Hōʻoia kēia hopena groundbreaking i ka hana polymer kuleana me ka ʻole o ka hoʻopilikia ʻana i ka maikaʻi a i ʻole ka pono, e hoʻohiki ana i nā pono hana he nui.

E hoʻopili me SILIKE i kēia lā e hoʻomaikaʻi i kāu hana polymer, hoʻonui i ka huahana, a hoʻokiʻekiʻe i ka maikaʻi o ka huahana!

Tel: +86-28-83625089 Email: amy.wang@silike.cn

Pūnaewele:www.siliketech.com

Ka manawa hoʻouna: Ian-10-2024