Pehea e hoʻomaikaʻi ai ka mea hoʻohui silicone i ka hana PS a me ka ʻili laumania?

Pehea e hoʻomaikaʻi ai ka mea hoʻohui silicone i ka hana PS a me ka ʻili laumania?

Ka hana ʻana o PS a me ka ʻili laumania, Mea hoʻohui Silicone, ʻO ka Masterbatch Silicone,

Wehewehena

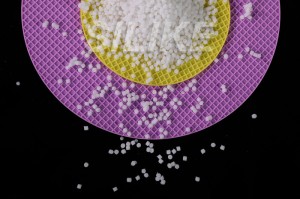

ʻO ka Masterbatch Silicone(Siloxane Masterbatch) ʻO LYSI-410 kahi ʻano pelletized me 50% ultra high molecular weight siloxane polymer i hoʻopuehu ʻia i loko o High impact polystyrene (HIPS). Hoʻohana nui ʻia ia ma ke ʻano he mea hoʻohui hana kūpono i ka ʻōnaehana resin PS kūpono e hoʻomaikaʻi i nā waiwai hana a hoʻololi i ka maikaʻi o ka ʻili.

E hoʻohālikelike i nā mea hoʻohui Silicone / Siloxane kaumaha haʻahaʻa maʻamau, e like me ka ʻaila Silicone, nā wai silicone a i ʻole nā ʻano hoʻohui hana ʻē aʻe, SILIKEʻO ka Masterbatch SiliconeManaʻo ʻia nā moʻo LYSI e hāʻawi i nā pono i hoʻomaikaʻi ʻia, e laʻa. ʻO ka emi ʻana o ka paheʻe ʻana o nā wili, ka hoʻokuʻu ʻana i ka ʻōpala i hoʻomaikaʻi ʻia, ka hōʻemi ʻana i ka drool make, ka coefficient friction haʻahaʻa, ka emi ʻana o nā pilikia pena a me ka paʻi ʻana, a me kahi ākea o nā hiki hana.

Nā Palena Kumu

| Papa | LYSI-410 |

| helehelena | ʻO ka pellet keʻokeʻo |

| Ka nui o ka silicone % | 50 |

| Kumu resin | Nā ʻūhā |

| ʻIneki heheʻe (230 ℃, 2.16KG) g/10min | 13.0 (waiwai maʻamau) |

| Ka nui o ka lāʻau (w/w) | 0.5~5 |

Nā Pōmaikaʻi

(1) Hoʻomaikaʻi i nā waiwai hana e komo pū ana me ka hiki ke kahe maikaʻi, ka hoʻemi ʻana i ka drool make extrusion, ka emi ʻana o ka torque extruder, ka hoʻopiha ʻana a me ka hoʻokuʻu ʻana i ka hoʻoheheʻe ʻana.

(2) Hoʻomaikaʻi i ka maikaʻi o ka ʻili e like me ka paheʻe ʻana o ka ʻili, ka haʻahaʻa o ka Coefficient of friction

(3) ʻOi aku ka pale ʻana i ka abrasion a me ke kahakaha ʻana

(4) ʻOi aku ka wikiwiki o ka hoʻopuka ʻana, e hōʻemi i ka helu hemahema o ka huahana.

(5) Hoʻonui i ke kūpaʻa e hoʻohālikelike ʻia me ke kōkua hana kuʻuna a i ʻole nā mea hoʻoluʻu

Nā noi

(1) Nā kāmaʻa TPR/TR

(2) Nā elastomers Thermoplastic

(3) Nā palakiko ʻenekinia

(4) Nā ʻōnaehana PS ʻē aʻe e kūlike me

Pehea e hoʻohana ai

Hiki ke hana ʻia ka masterbatch silicone moʻo SILIKE LYSI ma ke ʻano like me ka mea lawe resin i hoʻokumu ʻia ai lākou. Hiki ke hoʻohana ʻia i ke kaʻina hana hoʻohuihui hoʻoheheʻe maʻamau e like me ka extruder screw Single / Twin, injection molding. Manaʻo ʻia kahi hui kino me nā pellets polymer puʻupaʻa.

Manaʻo ʻia ka lāʻau

Ke hoʻohui ʻia i ka polyethylene a i ʻole thermoplastic like ma 0.2 a 1%, manaʻo ʻia ka hoʻomaikaʻi ʻana i ka hana ʻana a me ke kahe o ka resin, me ka hoʻopiha ʻana i ka mold maikaʻi, ka liʻiliʻi o ka extruder torque, nā lubricants kūloko, ka hoʻokuʻu ʻana o ka mold a me ka wikiwiki o ka throughput; Ma kahi pae hoʻohui kiʻekiʻe, 2 ~ 5%, manaʻo ʻia nā waiwai ʻili i hoʻomaikaʻi ʻia, me ka lubricity, ka paheʻe, ka coefficient haʻahaʻa o ka friction a me ka pale ʻana i ka mar/scratch a me ka abrasion.

Pūʻolo

25Kg / ʻeke, ʻeke pepa hana lima

Ka Waihona

E lawe ʻia ma ke ʻano he kemika ʻaʻole weliweli. E mālama i kahi anuanu a maikaʻi ka ea.

Ola papa

E mau ana nā ʻano kumu no 24 mau mahina mai ka lā hana, inā mālama ʻia i kahi mālama i ʻōlelo ʻia.

ʻO Chengdu Silike Technology Co., Ltd kahi mea hana a me ka mea hoʻolako i nā mea silicone, nāna i hoʻolaʻa i ka R&D o ka hui pū ʻana o Silicone me nā thermoplastics no 20+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnPS sheet is a material made of general-purpose polystyrene resin, some of our PS material clients told us when their downstream client produces 40 thread thickness polystyrene sheets if 50 sheets are cut at the same time, the surface of the products will have fuzz flash issues. when added SILIKE silicone additive to polystyrene at 2.0%, improved processing and flow of the resin are expected, in addition, the final PS sheet has good toughness, smooth surface that can cut PS sheet in a wanton shape, get good kerf and smooth edge.

Nā mea hoʻohui silicone manuahi a me nā laʻana Si-TPV ma mua o 100 mau papa

ʻAno laʻana

$0

- 50+

nā papa Silicone Masterbatch

- 10+

nā papa Silicone Powder

- 10+

nā papa Anti-scratch Masterbatch

- 10+

nā papa Anti-abrasion Masterbatch

- 10+

nā māka Si-TPV

- 8+

nā papa Silicone Wax

-

Kelepona

-

Leka uila

-

Whatsapp

Whatsapp

-

Luna

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur